Hello All,

I been reading hydraulics 101 by Mark ( an excellent work, thank you Mark ) and also plumbing FAQ by others.

I keep reading about maximum water velocity allowed and I was concern about my filter performance if water velocity is too high. I know anything moving too fast is not good for filters.

In one of my line of work with diesel engine fuel filtration system, maximum flow by engine total fuel demand ( burn & return ) and all pipe fittings ( elbow, reducers & etc ) is something I have always pay attention to. However pool is more complicated because of the long pipe run and so many elbows and so on. Worst of all, I never got involved in my pool building at all, I leave it to the so called "professional."

I am trying to source a Blue & White series 300 flow meter and fortunately there is a Indonesian dealer. I hope they stock what I need. I just emailed them.

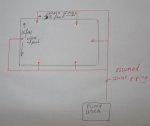

It seems it is so wrong based on sources I am reading, that my fix mount 2HP Hayward Pump is married to 1.5" PVC pipe both suction and entire discharge piping. This is why I wanted to get that flowmeter to know how bad is the friction loss or whatever detrimental effect is going on. I been searcing the web to try to figure out what are the complete negative effects if a filtration system supposedly using a 2" pipe and instead 1.5" pipe installed but I can't find any.

I have a Pentair 1.5HP on trolley as back up. If needed, I may switch that with the 2 HP Hayward, so that my fix mount pump becomes 1.5HP and can run more effieciently with 1.5" plumbing. Next is to buy a new pump next time that Hayward come of age ( its only 2 years old now ). I also like the Pentair pump better, it is so much more quiet than the Hayward. Maybe the Hayward is noiser because of plumbing resistance of the pool, where my Pentair on trolley only has short in and out hoses. The motors are the same, Smith something. I maybe hearing impeller noise ??

Do I loose a lot of filtration capability or performance on a system with increased water velocity ?

Hayward guideline stated 6-8 feet/sec maximum for suction and 10 ft/sec maximum for disharge.

Vampire electric bills I can live with but filtration system not working at its best in terms of particle capture, I consider that a failure. Loosing money on electrical bills and at the same time not getting my investment from the filters...so sad. I rather dump some more money now and correct the filtering situation, regardless that 1.5" pipe is wrong to begin with. I can't change pipes, its all inside concrete.

The typical filter data sheet always put commercial operation must have lower flow for a typical filter or bigger filter than a residensial one. Its like 50% flow reduction for commercial filters application.

Now, filters always talk of GPM of flow, based on square feet of filter material. Pipe talk of GPM and water velocity.

For a smaller pipe to flow same GPM compared to next bigger pipe, water velocity must increase.

What actually will happen if my setup up of 2HP pump, which supposedly must use 2" pipe at least .....get plumbed with 1.5" pipe ?

The filters I have are designed with 2" port, but plumbed with 1.5". Is fair to say that I will have higher water velocity within the filter housing, even though the filters internal water plumbing are for 2" ( or sized at 2" ). I don't understand hydraulics to verify water velocity in this kind of scenario. All I know back pressure or total dynamic head will increase for sure due to smaller pipe size being used.

Anyone who can help, I will be most grateful.

Thanks,

Surya

I been reading hydraulics 101 by Mark ( an excellent work, thank you Mark ) and also plumbing FAQ by others.

I keep reading about maximum water velocity allowed and I was concern about my filter performance if water velocity is too high. I know anything moving too fast is not good for filters.

In one of my line of work with diesel engine fuel filtration system, maximum flow by engine total fuel demand ( burn & return ) and all pipe fittings ( elbow, reducers & etc ) is something I have always pay attention to. However pool is more complicated because of the long pipe run and so many elbows and so on. Worst of all, I never got involved in my pool building at all, I leave it to the so called "professional."

I am trying to source a Blue & White series 300 flow meter and fortunately there is a Indonesian dealer. I hope they stock what I need. I just emailed them.

It seems it is so wrong based on sources I am reading, that my fix mount 2HP Hayward Pump is married to 1.5" PVC pipe both suction and entire discharge piping. This is why I wanted to get that flowmeter to know how bad is the friction loss or whatever detrimental effect is going on. I been searcing the web to try to figure out what are the complete negative effects if a filtration system supposedly using a 2" pipe and instead 1.5" pipe installed but I can't find any.

I have a Pentair 1.5HP on trolley as back up. If needed, I may switch that with the 2 HP Hayward, so that my fix mount pump becomes 1.5HP and can run more effieciently with 1.5" plumbing. Next is to buy a new pump next time that Hayward come of age ( its only 2 years old now ). I also like the Pentair pump better, it is so much more quiet than the Hayward. Maybe the Hayward is noiser because of plumbing resistance of the pool, where my Pentair on trolley only has short in and out hoses. The motors are the same, Smith something. I maybe hearing impeller noise ??

Do I loose a lot of filtration capability or performance on a system with increased water velocity ?

Hayward guideline stated 6-8 feet/sec maximum for suction and 10 ft/sec maximum for disharge.

Vampire electric bills I can live with but filtration system not working at its best in terms of particle capture, I consider that a failure. Loosing money on electrical bills and at the same time not getting my investment from the filters...so sad. I rather dump some more money now and correct the filtering situation, regardless that 1.5" pipe is wrong to begin with. I can't change pipes, its all inside concrete.

The typical filter data sheet always put commercial operation must have lower flow for a typical filter or bigger filter than a residensial one. Its like 50% flow reduction for commercial filters application.

Now, filters always talk of GPM of flow, based on square feet of filter material. Pipe talk of GPM and water velocity.

For a smaller pipe to flow same GPM compared to next bigger pipe, water velocity must increase.

What actually will happen if my setup up of 2HP pump, which supposedly must use 2" pipe at least .....get plumbed with 1.5" pipe ?

The filters I have are designed with 2" port, but plumbed with 1.5". Is fair to say that I will have higher water velocity within the filter housing, even though the filters internal water plumbing are for 2" ( or sized at 2" ). I don't understand hydraulics to verify water velocity in this kind of scenario. All I know back pressure or total dynamic head will increase for sure due to smaller pipe size being used.

Anyone who can help, I will be most grateful.

Thanks,

Surya