For starters, I am a complete pool newbie. I have probably spent 30-40 hours over the past couple of weeks reading the TFP forum. I have learned so much and feel very confident about dealing with the PB.  So, thank you to all the people on this forum who have posted questions and answers.

So, thank you to all the people on this forum who have posted questions and answers.

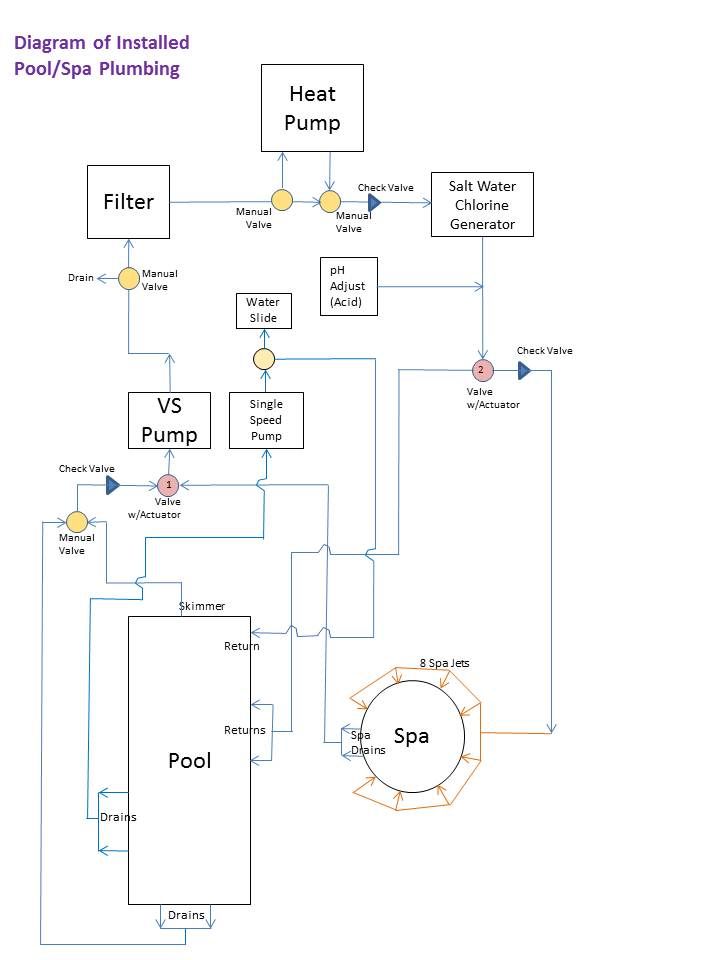

We are planning to install a fiberglass pool (16' x 37') and a spillover fiberglass spa (8' diameter). We also plan to have the decking plumbed for a possible future waterslide. We plan to go with cartridge filter, SWG, and a Heat Pump.

I have seen plumbing diagrams for using 1 pump for this configuration or using 2 pumps.

I'm looking for advice on which way to go.

With 2 pumps, will I need 2 filters?

With just 1 pump, could people use the spa, swim in the pool, and use the waterslide simultaneously? Or, would 2 pumps be required?

I'm thinking that whether we go with 1 or 2 pumps, both would be 2 speed. Is that the best approach? Our electric rate is relatively low.

What other issues should I be considering as far as deciding which way to go?

Thanks.

So, thank you to all the people on this forum who have posted questions and answers.

So, thank you to all the people on this forum who have posted questions and answers.

We are planning to install a fiberglass pool (16' x 37') and a spillover fiberglass spa (8' diameter). We also plan to have the decking plumbed for a possible future waterslide. We plan to go with cartridge filter, SWG, and a Heat Pump.

I have seen plumbing diagrams for using 1 pump for this configuration or using 2 pumps.

I'm looking for advice on which way to go.

With 2 pumps, will I need 2 filters?

With just 1 pump, could people use the spa, swim in the pool, and use the waterslide simultaneously? Or, would 2 pumps be required?

I'm thinking that whether we go with 1 or 2 pumps, both would be 2 speed. Is that the best approach? Our electric rate is relatively low.

What other issues should I be considering as far as deciding which way to go?

Thanks.