I had a Hayward Max-Flo 2 - 2 speed 1 HP 230 volt pump go bad in August and the replacement just went today. I installed a roof solar system and I'm wondering if I'm not using enough HP. I don't have a vacuum relief valve in the solar and I didn't notice more than about a 2 PSI difference between the solar system on and off.

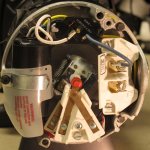

The pump motor looks burned. My flow has been fine and I would think the motor has thermal protection if it got too warm. I've put my hand on the pump while running and It's hot but I don't have to remove my hand right away.

The distance to the top of the roof solar is maybe 12 feet but again the water does not drain out and so it pumps anmd down at the same time. I'm using 2 inch pipe throughout.

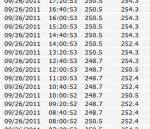

Should mention that the PSI at the filter is 16 PSI while running solar and about 14-15 PSI when just connected to the filter.

The pump motor looks burned. My flow has been fine and I would think the motor has thermal protection if it got too warm. I've put my hand on the pump while running and It's hot but I don't have to remove my hand right away.

The distance to the top of the roof solar is maybe 12 feet but again the water does not drain out and so it pumps anmd down at the same time. I'm using 2 inch pipe throughout.

Should mention that the PSI at the filter is 16 PSI while running solar and about 14-15 PSI when just connected to the filter.