This might be of use to folks who have a 2 speed pump (or anyone that doesn't, like myself) and wants to get their LQ to flow without having to to adjust the skimmer valve. It also may be old news for some, but it is new to me.

I don't know how many people were silently suffering with a no/low flow problem from their LQ on their above ground pools like I was, but the problem was deemed unacceptable and I knew there had to be a solution. I scoured the LQ board and came across a hint from mas985, author of "Hydraulics 101 - Have you lost your head?", and much other fine information in the "Pumping Station" section.

He said

Well thank you Giovanni Battista Venturi the Italian physicist for your discovery, and to mas985 for suggesting it. It works! I went from NO flow, to a reading of 4.5 with the venturi injection. My pump pressure before the mod was 11, afterwards was 10~10.5. OoRahh!! Plus the fact that the LQ is operating as advertised! I've reduced the 1 1/2 inch pipe down to 3/4 inch for approx a 6 inch span.

I don't know how many people were silently suffering with a no/low flow problem from their LQ on their above ground pools like I was, but the problem was deemed unacceptable and I knew there had to be a solution. I scoured the LQ board and came across a hint from mas985, author of "Hydraulics 101 - Have you lost your head?", and much other fine information in the "Pumping Station" section.

He said

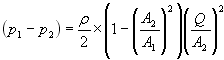

"...a very short (< 6") section of smaller diameter pipe which would simulate a venturi. The injection point would be in the smaller pipe.

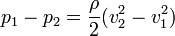

The venturi concept relies upon the fact that pressure will drop when water velocity increases. So by downsizing the pipe for a short section, you will get a pressure drop (more suction) but it is temporary unlike head loss with a valve is. The pressure rises once again once the pipe expands back to the original size."

Well thank you Giovanni Battista Venturi the Italian physicist for your discovery, and to mas985 for suggesting it. It works! I went from NO flow, to a reading of 4.5 with the venturi injection. My pump pressure before the mod was 11, afterwards was 10~10.5. OoRahh!! Plus the fact that the LQ is operating as advertised! I've reduced the 1 1/2 inch pipe down to 3/4 inch for approx a 6 inch span.