- Dec 13, 2009

- 116

- Pool Size

- 32000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

We completed our pool last year and have moved on (finally) to starting the pool house. I am doing the floor system, interior finish, electrical, plumbing myself, but having a local shed/garage building get the shell up on top of my deck framing. They can do it very efficiently and allow upgrades (including Tyvek house wrap, 2 x 6 rafters, etc) that allow for it to be finished and even heated/cooled.

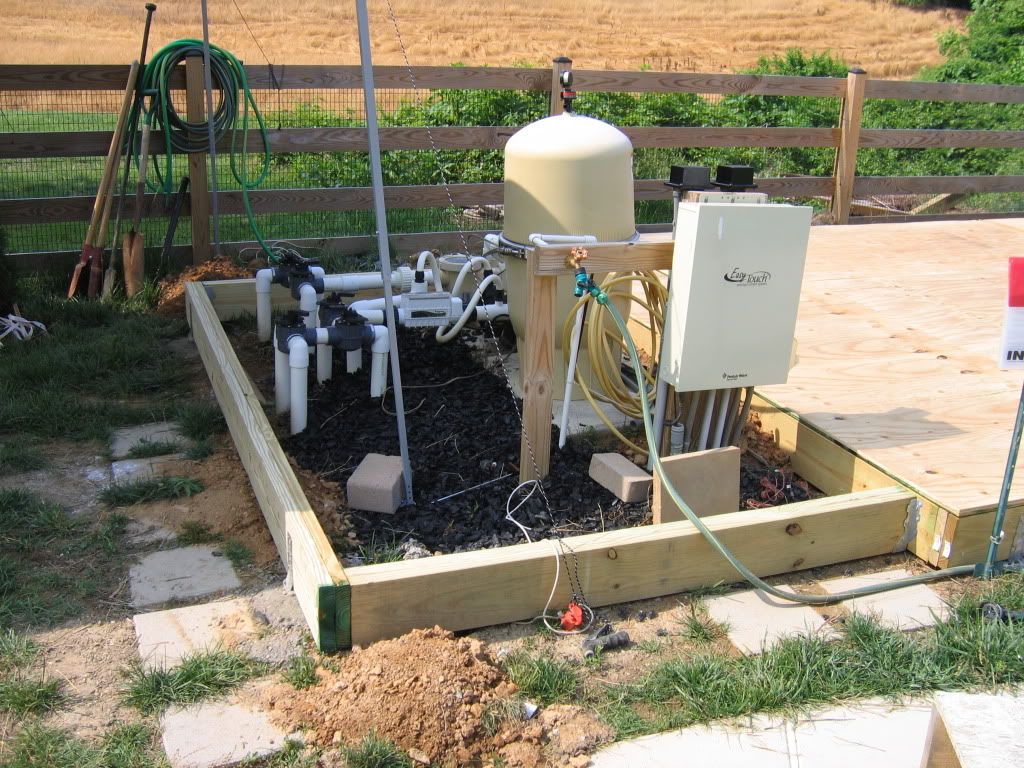

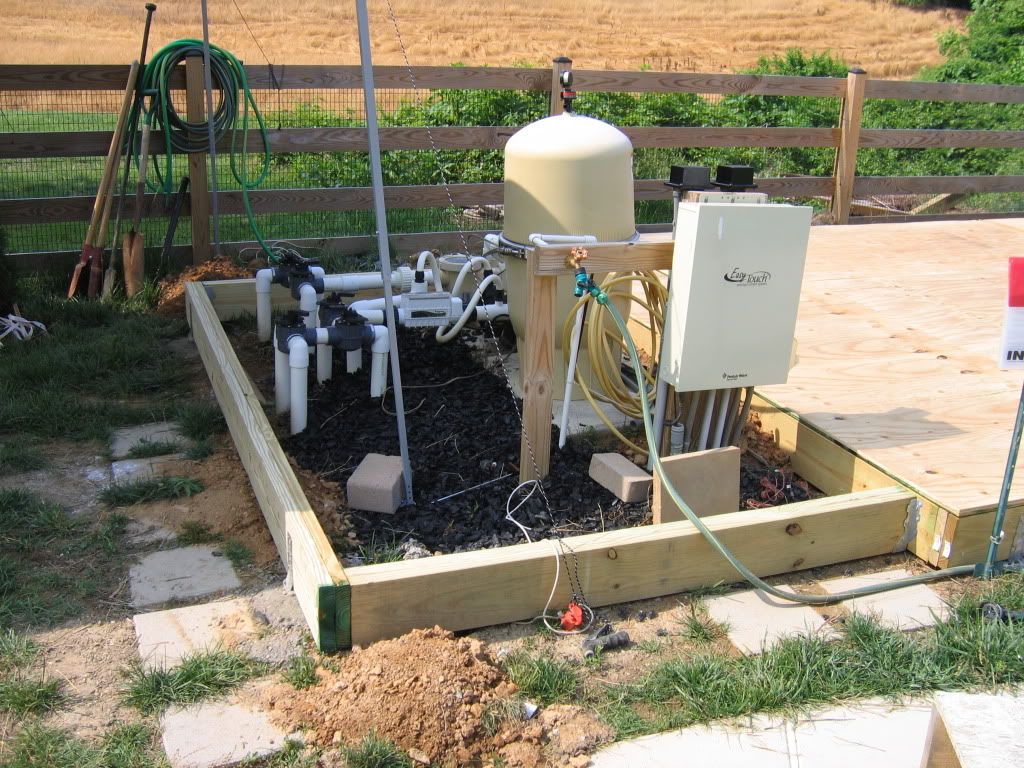

The pool house is 16 x 12, with an additional 6 x 10 area which will shelter the equipment pad. Of the 16 x 12 main structure, we are carving out a 4 x 8 chemical and supply closet on one of the short sides (which will be separately vented). The remainder of the area will be finished, have a kitchenette, small changing room and A/V.

Deck Framing. I also used a contractor-grade woven fabric on the ground for weed blockage and a seperate piece tacked to the underside of the framing to keep insects out.

Broader view of framing. All PT 2 x 8s. Triple beam front and back and doubled joists on each end.

Detail of beams at corner:

Insulation installed (R30)

Vapor Barrier (in case we decide to heat/cool in the future):

Decking installed. I used two layers of 1/2" CDX screwed with 2 1/2" ss screws and adhesive between the layers. I also rolled on wood preservative to the underside of the first layer for added rot and insect protection.

Detail of framing at equipment pad:

The pool house is 16 x 12, with an additional 6 x 10 area which will shelter the equipment pad. Of the 16 x 12 main structure, we are carving out a 4 x 8 chemical and supply closet on one of the short sides (which will be separately vented). The remainder of the area will be finished, have a kitchenette, small changing room and A/V.

Deck Framing. I also used a contractor-grade woven fabric on the ground for weed blockage and a seperate piece tacked to the underside of the framing to keep insects out.

Broader view of framing. All PT 2 x 8s. Triple beam front and back and doubled joists on each end.

Detail of beams at corner:

Insulation installed (R30)

Vapor Barrier (in case we decide to heat/cool in the future):

Decking installed. I used two layers of 1/2" CDX screwed with 2 1/2" ss screws and adhesive between the layers. I also rolled on wood preservative to the underside of the first layer for added rot and insect protection.

Detail of framing at equipment pad: