Hi Folks, first post so here goes.

After 4 years of planning (on and off), I am in the middle of building my pool myself.

I had the plumbing more or less worked out but decided to re-check

my plumbing layout with one of my suppliers who is also a pool builder and plumber.

I wanted to check with people here to see if they agree with his suggestions.

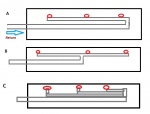

I liked my original plan because it was simple:

The pool is 23ftX13ft by 5ft deep and will contain about 10,000 gallons. No deep end. No main drain. Hydroplug in floor.

1 large skimmer box placed at center of long wall. 2Xwall suctions on either side of skimmer towards corners. All on same plumbing line.

Opposite long wall, 3X eyeball returns.

1hp pump (which I thought was oversize)

2" pressure pipe

When I add a solid fuel heater at a later date, I would join a heat exchanger into the return line.

So he advised me that:

A) the skimmer is all that is required, no wall suctions necessary and that even on their own plumbing line, if used at the same time as the skimmer, they will

reduce the efficacy of the skimmer.

B) 4 eyeballs on the opposite wall not three as the eyeballs do most of the work of circulation not wall suctions.

C) He always puts a 1.5hp pump in as any less and the vacuum cleaners dont work properly.

D) Heated water needs to be pumped in on a separate circuit using a 2nd pump, two suctions with two returns. I really dont want to do it this way if possible.

I did check my original design and pump/filter spec with Pentair and another parts supplier and they said it was fine. Please could people advise.

thanks.

After 4 years of planning (on and off), I am in the middle of building my pool myself.

I had the plumbing more or less worked out but decided to re-check

my plumbing layout with one of my suppliers who is also a pool builder and plumber.

I wanted to check with people here to see if they agree with his suggestions.

I liked my original plan because it was simple:

The pool is 23ftX13ft by 5ft deep and will contain about 10,000 gallons. No deep end. No main drain. Hydroplug in floor.

1 large skimmer box placed at center of long wall. 2Xwall suctions on either side of skimmer towards corners. All on same plumbing line.

Opposite long wall, 3X eyeball returns.

1hp pump (which I thought was oversize)

2" pressure pipe

When I add a solid fuel heater at a later date, I would join a heat exchanger into the return line.

So he advised me that:

A) the skimmer is all that is required, no wall suctions necessary and that even on their own plumbing line, if used at the same time as the skimmer, they will

reduce the efficacy of the skimmer.

B) 4 eyeballs on the opposite wall not three as the eyeballs do most of the work of circulation not wall suctions.

C) He always puts a 1.5hp pump in as any less and the vacuum cleaners dont work properly.

D) Heated water needs to be pumped in on a separate circuit using a 2nd pump, two suctions with two returns. I really dont want to do it this way if possible.

I did check my original design and pump/filter spec with Pentair and another parts supplier and they said it was fine. Please could people advise.

thanks.