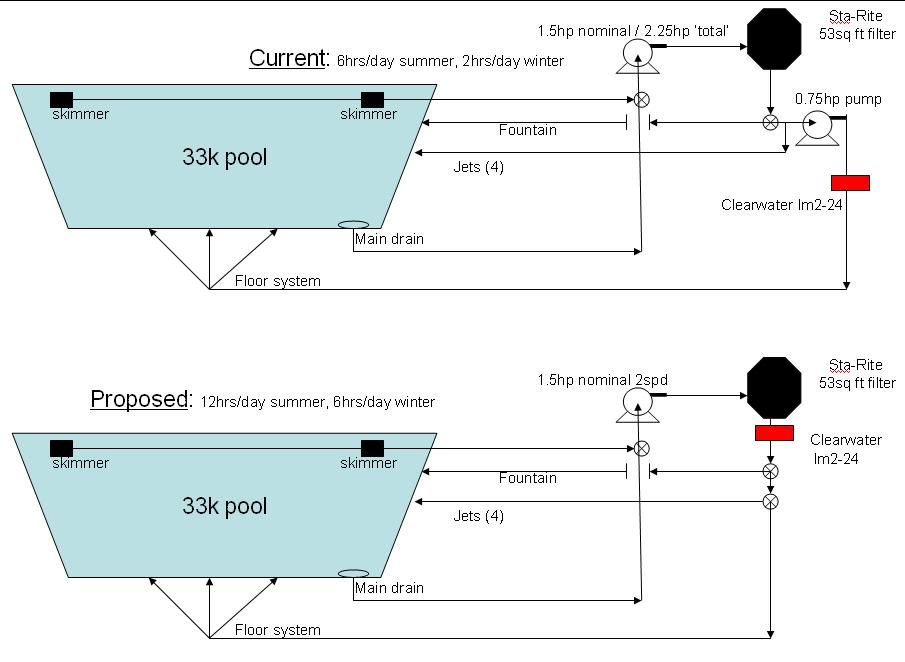

The current system is as below, quite complex: 2 pumps, lots of valves, jets, fountain, and floor system, salt cell. Acid dosing as well.

Issues with the current system:

-energy hog

-when both pumps are running, floor system is very strong but jets (and Leaf Devil, not shown) are very weak

-Cannot balance flow between jets & floor system

I normally run just the big 1.5hp nominal pump. The jets are strong, the flow through the SWG and floor system is just adequate. I’m sure there’s excess pressure drop pushing through the stopped 0.75hp pump.

Proposed system:

-Move SWG directly to outlet of DE filter

-Install one new big 2spd pump

-change valving to allow balancing floor system and jets

-run the new pump more hours at lower speed

1)thoughts on the overall plan?

2)Look at my pictures: can I re-use the valves? They look glued to me, in which case I’m out of luck, correct?

3)What am I missing?

Thanks!!

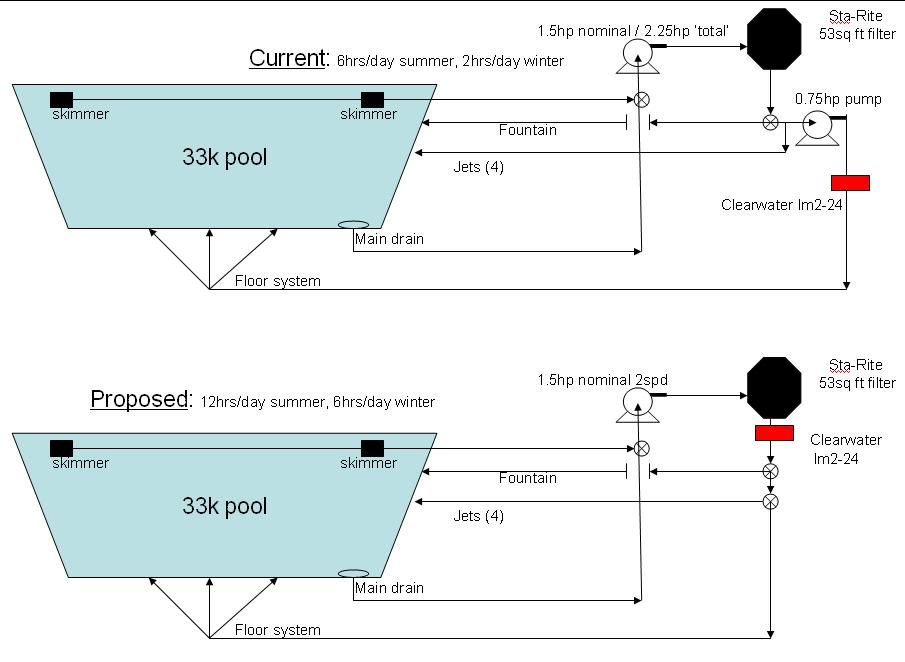

Issues with the current system:

-energy hog

-when both pumps are running, floor system is very strong but jets (and Leaf Devil, not shown) are very weak

-Cannot balance flow between jets & floor system

I normally run just the big 1.5hp nominal pump. The jets are strong, the flow through the SWG and floor system is just adequate. I’m sure there’s excess pressure drop pushing through the stopped 0.75hp pump.

Proposed system:

-Move SWG directly to outlet of DE filter

-Install one new big 2spd pump

-change valving to allow balancing floor system and jets

-run the new pump more hours at lower speed

1)thoughts on the overall plan?

2)Look at my pictures: can I re-use the valves? They look glued to me, in which case I’m out of luck, correct?

3)What am I missing?

Thanks!!