Problem has been solved. It was due to the pipes being installed backwards into the heater. From digging into some more of the equipment diagrams of the heater I discovered there are a few valves that would have severely restricted flow... low and behold, flipping the input/outputs solved the problem of everything...

- The spa blows with jets now and strong power, the pool returns as well.

- The pump is noticeably quieter.

- The cascade now operates at >1500 less RPM than before.

- The pool has noticeable suction.

- The pump no longer evacuates water onto the deck via the skimmer when shut down.

- Even though I wont do it, when I set the intake to 50,50 and return 100 spa, the spa does not drain, it cascades.

- The system is running at least 10 PSI less-

IN- 100 pool, OUT- 100 pool - 23.5PSI

IN- 100 pool, OUT- 100 spa - 23.5PSI

IN- 100 spa, OUT- 100 spa - 24.5PSI

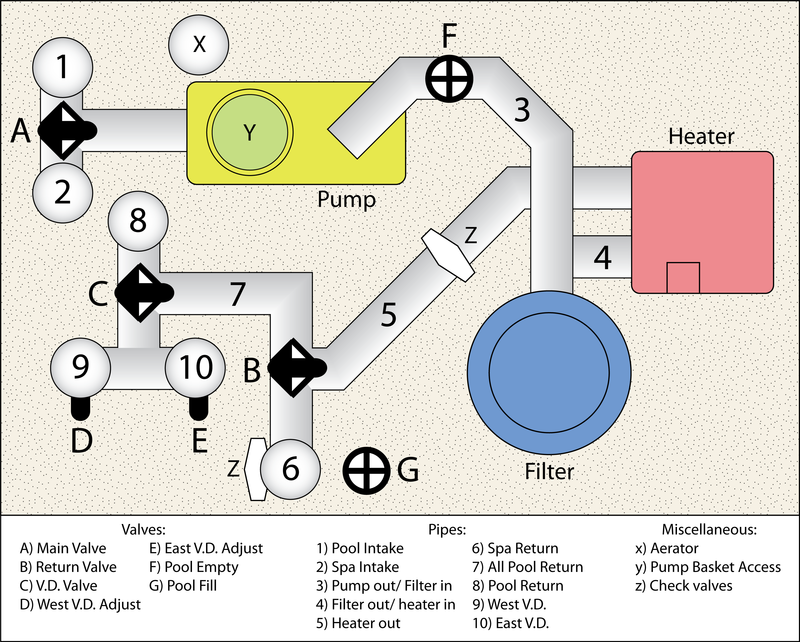

All it took was taking this-

and turning it into this-

The main question I guess is, why after ~2 months of the equipment being hooked up... and the plumber being here 2 months ago, last week, and this morning... the start-up guy being here on Saturday... and my 'project manager' (I wont kid, she was on site maybe <20 minutes total the entire build)... NONE of them noticed it...

I'm going to call Pentair's help line tomorrow and get some comments from them on if running the system backwards for ~30 hours over 3 days could have caused any foreseeable damage (stress on the pump, stress on the heater) and will notify the PB... but hey, the system WORKS!