I bought a house last year with an in ground salt system pool approx 26000 gallons. At the end of the year the pump was getting really hot and sounded like the bearings were shot. I just got around to taking the pump motor off and it is toast. It was a [FONT=open_sansregular]Emerson EB128 56 J-Frame C-Flange Single Speed 1HP Full Rated Pool and Spa Motor. I ran it about 4 hrs per day and had zero problems with water quality. I found the same motor for $151 but wanted to know if I should bother looking into a higher efficiency model and what to look for if I did? [/FONT]

What type of replacement pump motor to get?

- Thread starter mf7365

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

It would be worth getting a 2 speed pump, same size. It would move half the water for a quarter of he electricity. You could run it twice a day 3 hours a day for extra skimming and save quite a bit of electricity.

Would this require any different wiring from what was already set up for the original pump?

What voltage is your setup currently setup for? That motor in particular is dual voltage 120/220V

PoolDV - I haven't ever disagreed with you, but on this one, "It would be worth getting a 2 speed pump, same size. It would move half the water for a quarter of he electricity. " - I do.

A 3-Phase, 2 speed ACIM type motor (sorry, when I say ACIM think "capacitor start" ) - If you go dig into the motor datasheets, you see you really only save about 10% of the electricity running between high and low speeds. It has to do with the fact that most of them are squirrel cage single winding motors (IE, inexpensive) so the speed control is simply exciting a delta wye bridge versus a parallel wye.

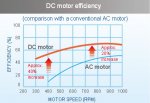

The big savings come with the BIGGER cost, where you get into variable frequency drives (VFD) - what we commonly call the Variable Speed Pumps. These actually modulate the PWM switching frequency to a brushless DC motor (rather than a big, heavy AC induction setup.) This modulation control is what gives us the ability to dial in specific RPM levels. But - these motors come at the cost, usually 2x to 3x, a 2-speed AC, because of the additional overhead in the digital controllers required to make them work.

(I'm always happy to talk motors - I do motor control for a living in the semiconductor world )

)

MF - as to the question if it requires any different wiring, again, just let us know if it's 120VAC or 22VAC setup. (take a picture of the wires going into the pump?)

PoolDV - I haven't ever disagreed with you, but on this one, "It would be worth getting a 2 speed pump, same size. It would move half the water for a quarter of he electricity. " - I do.

A 3-Phase, 2 speed ACIM type motor (sorry, when I say ACIM think "capacitor start" ) - If you go dig into the motor datasheets, you see you really only save about 10% of the electricity running between high and low speeds. It has to do with the fact that most of them are squirrel cage single winding motors (IE, inexpensive) so the speed control is simply exciting a delta wye bridge versus a parallel wye.

The big savings come with the BIGGER cost, where you get into variable frequency drives (VFD) - what we commonly call the Variable Speed Pumps. These actually modulate the PWM switching frequency to a brushless DC motor (rather than a big, heavy AC induction setup.) This modulation control is what gives us the ability to dial in specific RPM levels. But - these motors come at the cost, usually 2x to 3x, a 2-speed AC, because of the additional overhead in the digital controllers required to make them work.

(I'm always happy to talk motors - I do motor control for a living in the semiconductor world

MF - as to the question if it requires any different wiring, again, just let us know if it's 120VAC or 22VAC setup. (take a picture of the wires going into the pump?)

I will admit that I have no direct experience with a 2 speed pump. I am only repeating what I have read here on many occasions. I guess I'll have to go do some research!

I can say that my variable speed pump is ridiculously cheap to run. I run it at 1100rpm for skimming, filtering and making chlorine and it uses 150 watts at 1100 rpm. At 10.25c/kWh I can run my pump 24x7 at 1100 rpm for less than 12 bucks a month.

Here's a variable speed pump for 650 bucks, Pentair SuperFlo VS Pump 342001 | Pentair 342001

Update:

I am back with more data to back up the assertion that a two speed pump moves half the water while using 25% (or less) of the electricity.

The Pump Affinity Law

The advantage of a small pump is explained by the Pump Affinity Law, which states that the power consumed by a pump is proportional to the cube of the flow rate. This means, for example, that if a pump’s flow rate is reduced by half, its power draw is reduced to one eighth. If you reduce a pump’s speed from 3,450 rpm to 2,400 rpm — a 30% reduction in speed — the watt draw drops from 2,000 watts to only 593 watts — a 70% reduction in power.

If you reduce the speed of a pump motor by half, you get half the water flow, so you will have to operate the pump for twice as long as you would if you used a pump with a more powerful motor. But since the low-speed motor only draws one-eighth as much power as the high-speed motor, it will only require one-quarter as much energy (in theory; actual savings are somewhat less than theoretical savings) to move the water with a smaller pump.

Read more:Is Your Pool an Energy Hog? | GreenBuildingAdvisor.com

Variable Speed Pool Pump or Dual Speed... Which is Best for Me? - INYOPools.com

The energy savings that are gained by replacing a single speed pump with either a dual speed or variable speed pump are based on an engineering principle known as the Pump Affinity Law. Without taking you back to high school algebra class, this principle states that the energy savings are disproportionately larger as you lower the speed of your pump. For example if you reduce the RPMs of your pump by 50% you don’t get a 50% energy savings you actually get a 75% energy savings

I can say that my variable speed pump is ridiculously cheap to run. I run it at 1100rpm for skimming, filtering and making chlorine and it uses 150 watts at 1100 rpm. At 10.25c/kWh I can run my pump 24x7 at 1100 rpm for less than 12 bucks a month.

Here's a variable speed pump for 650 bucks, Pentair SuperFlo VS Pump 342001 | Pentair 342001

Update:

I am back with more data to back up the assertion that a two speed pump moves half the water while using 25% (or less) of the electricity.

The Pump Affinity Law

The advantage of a small pump is explained by the Pump Affinity Law, which states that the power consumed by a pump is proportional to the cube of the flow rate. This means, for example, that if a pump’s flow rate is reduced by half, its power draw is reduced to one eighth. If you reduce a pump’s speed from 3,450 rpm to 2,400 rpm — a 30% reduction in speed — the watt draw drops from 2,000 watts to only 593 watts — a 70% reduction in power.

If you reduce the speed of a pump motor by half, you get half the water flow, so you will have to operate the pump for twice as long as you would if you used a pump with a more powerful motor. But since the low-speed motor only draws one-eighth as much power as the high-speed motor, it will only require one-quarter as much energy (in theory; actual savings are somewhat less than theoretical savings) to move the water with a smaller pump.

Read more:Is Your Pool an Energy Hog? | GreenBuildingAdvisor.com

Variable Speed Pool Pump or Dual Speed... Which is Best for Me? - INYOPools.com

The energy savings that are gained by replacing a single speed pump with either a dual speed or variable speed pump are based on an engineering principle known as the Pump Affinity Law. Without taking you back to high school algebra class, this principle states that the energy savings are disproportionately larger as you lower the speed of your pump. For example if you reduce the RPMs of your pump by 50% you don’t get a 50% energy savings you actually get a 75% energy savings

Would this require any different wiring from what was already set up for the original pump?

No, you need to know if you have a 110v or 220v pump now and get one that is the same voltage. A two speed pump uses a switch on the back of the pump to change from low speed to high speed. Sometimes they need to be ordered separately.

PoolDV - both of those articles are good, but remember I said if you want the BIGGER savings, go with a VSP  (which, both articles also agree to!)

(which, both articles also agree to!)

I agree with you though - my VSP costs me nothing to run either, hence just leaving it on at 1100 RPM most of the time.

But...Simply put, BLDC VSP's are much more efficient than multi-speed ACIM. The Pump affinity law is a good estimator, but when you start looking at things like slip, rotor torque, switching losses, control, tune-ability to peak efficiency (who really needs to run the pump at full tilt anyway?) etc, BLDC VSP simply wins, but (as I've said in every other post on the topic) you have to weigh the up-sell cost of the VSP versus a 2 speed, versus your electricity rates.

What will be even more interesting is if the power companies ever start charging the consumer user for Power Factor mis-match. Technically, if you have a smart-meter on the side of your house, they can already figure this out. Industrial power gets charged based on this (it's the difference in what is "used" versus what is "delivered" - I know, sounds kind of stupid) - I think it's something like $9 per kWH here if you are outside of the 0.95 to unity range.

Again I don't think we're disagreeing on anything here

I agree with you though - my VSP costs me nothing to run either, hence just leaving it on at 1100 RPM most of the time.

But...Simply put, BLDC VSP's are much more efficient than multi-speed ACIM. The Pump affinity law is a good estimator, but when you start looking at things like slip, rotor torque, switching losses, control, tune-ability to peak efficiency (who really needs to run the pump at full tilt anyway?) etc, BLDC VSP simply wins, but (as I've said in every other post on the topic) you have to weigh the up-sell cost of the VSP versus a 2 speed, versus your electricity rates.

What will be even more interesting is if the power companies ever start charging the consumer user for Power Factor mis-match. Technically, if you have a smart-meter on the side of your house, they can already figure this out. Industrial power gets charged based on this (it's the difference in what is "used" versus what is "delivered" - I know, sounds kind of stupid) - I think it's something like $9 per kWH here if you are outside of the 0.95 to unity range.

Again I don't think we're disagreeing on anything here

Attachments

Good stuff for sure!

So, to summarize for the OP. A two speed pump is better than a single speed pump. And a variable speed pump is better than a two speed pump.

Get the best pump you can afford.

So, to summarize for the OP. A two speed pump is better than a single speed pump. And a variable speed pump is better than a two speed pump.

Get the best pump you can afford.

- May 3, 2007

- 16,820

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Not the case for two speed motors used on residential pool pumps. These have a second 4-pole winding for low speed so efficiency loss is only about 50%. If you look at the Energy Star pump test data, the low speed on a two speed pump uses less than 1/4th the power of high speed.A 3-Phase, 2 speed ACIM type motor (sorry, when I say ACIM think "capacitor start" ) - If you go dig into the motor datasheets, you see you really only save about 10% of the electricity running between high and low speeds. It has to do with the fact that most of them are squirrel cage single winding motors (IE, inexpensive) so the speed control is simply exciting a delta wye bridge versus a parallel wye.

Also, because of the cost difference between two speed and VS pumps, in some cases, a two speed pump can have a lower life time cost than a VS pump. It just depends on what you pay for electricity and what you pay for the pump and how long you run the pump each day.

Sorry to get back to the conversation late. Been busy. On the motor it says Volts 230/115 , Hz 60, HP 1, S.F. 1.40 I live in Northwest Ohio and only ran my pump from June-August last year, with maybe half of September before closing up shop. So I guess my issue is: based on the extra cost of a 2 speed or VSP motor over a high efficiency single speed how much savings will I realistically see?Because over only a 3 1/2 month operating window it could be awhile before I make back the cost difference in electricity savings.

- May 3, 2007

- 16,820

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

- May 3, 2007

- 16,820

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Assuming you just replace the motor of your current pump without replacing the entire pump, at that electrical rate, it would take over 114 months (32 years) of operation for a VS to become more cost effective than a two speed (assumes a $300 price difference). Pumps don't generally last that long. But it would take less than 18 months for a two speed to become more economical than a single speed (assumes a $100 price difference).

So if I understand this right, it would take approximately 5 years for the op to start saving money if he buys a 2-speed over a single speed motor.

For simplicity I would stick with the single speed motor, no need to change the wiring, or add a switch if needed, no need to manually switch the speed, and the pool will skim better with the single speed motor. Just my .02.

For simplicity I would stick with the single speed motor, no need to change the wiring, or add a switch if needed, no need to manually switch the speed, and the pool will skim better with the single speed motor. Just my .02.

- May 3, 2007

- 16,820

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Yes and it assumed 4 hours per day for the single speed which for most pools is more than enough.

However, for the two speed, I assumed 1 hour on high and 6 on low but the op may not need that much so break even could be sooner.

However, for the two speed, I assumed 1 hour on high and 6 on low but the op may not need that much so break even could be sooner.

Thanks. I was leaning in the direction of sticking with a single speed due to the other added cost factor of also having to put in a new timer. I ran the pump 4 hours a day last summer, but was thinking about maybe going down to 3. Is that to low? What is the life expectancy of a single speed vs. dual speed considering my run times and only using the pump for 3 1/2 months each year?

- May 3, 2007

- 16,820

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

I run at 1 hour on high speed and the only reason I run on low speed is because of my SWG. During the winter when I don't need as much FC, I usually just run on high speed for the cleaner and the skimmer. So 3 hours is fine and even less may be possible.

Also given your location, weather can shorten the life of a motor too. How are you protecting the motor during the winter months?

I don't think they are much different. A two speed may or may not have more parts (e.g. centrifugal switch) but the key item that shortens the life of a pump motor is not even on the motor. That would be the shaft seal. Often times they fail and the owner doesn't notice or ignores the leak under the pump. This water can get into the motor bearings and shorten the life of the bearing significantly. If cared for properly, a pump motor could last as long as 100000 hours of run time. But most pump motors don't last this long because they are not cared for properly.What is the life expectancy of a single speed vs. dual speed considering my run times and only using the pump for 3 1/2 months each year?

Also given your location, weather can shorten the life of a motor too. How are you protecting the motor during the winter months?

I bought the house last spring so this was my first winter. I have a large tarp covering the entire system. Filter, pump, SWG, etc. But based on the condition the old pump was in when I disconnected it, (heavily corroded) I plan on taking the motor off each winter. It's not that big a deal. Took maybe 10 minutes.

- May 3, 2007

- 16,820

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

fields_g

Well-known member

Don't forget about rebates when you are looking at price. I got a Hayward Maxflo VS for $600+tax+shipping and got a $400 rebate through my utility. I think my payback could be as quick as 2 years. Pentair's Utility Links

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.