Hello all,

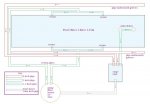

Just trying to design the piping for a deck level indoor pool which has been partially built. A lot of the piping has already been laid but the only pipe which can't be changed is the 2 inch pipe from the main drain to the surge tank. Ultimately though, they will all be covered in concrete. I'm trying to achieve a turnover time of 4.5 hours which will mean a flow of 66 GPM.

At present, my quandary is what size pipe to use from surge tank to pump (see drawing).

I'm new to all this, so have a few basic questions:

1) Can this pipe be too big?

i.e. a 2.5 inch pipe can achieve 90 gpm at 6ft/sec, but, what the ****, why not put in a 3 inch pipe. Then I know it is definitely big enough for all required flow rates. Are there any disadvantages to a big pipe other than cost?

2) Do the current pipe sizes look ok?

I assume the pipes which feed the surge tank from the pool via gravity can never be too big.

3) In the Hydraulics 101 thread ( http://www.troublefreepool.com/threads/830-Hydraulics-101-Have-you-lost-your-head ) it says:

"On the return side of the pump, multiple lines can help reduce head loss as well but the number of return lines should never exceed the number of suction or pump cavitation could become an issue."

I don't understand why. Please can someone explain.

4) Also in the Hydraulics 101 thread there is an "Equivalent Pipe/Fitting Size" table. I can't get my head round why where N=1 the equivalent pipe size isn't equal to the actual pipe size. I must be making a fundamental misunderstanding here but don't know what it is.

Thanks

Nick

Just trying to design the piping for a deck level indoor pool which has been partially built. A lot of the piping has already been laid but the only pipe which can't be changed is the 2 inch pipe from the main drain to the surge tank. Ultimately though, they will all be covered in concrete. I'm trying to achieve a turnover time of 4.5 hours which will mean a flow of 66 GPM.

At present, my quandary is what size pipe to use from surge tank to pump (see drawing).

I'm new to all this, so have a few basic questions:

1) Can this pipe be too big?

i.e. a 2.5 inch pipe can achieve 90 gpm at 6ft/sec, but, what the ****, why not put in a 3 inch pipe. Then I know it is definitely big enough for all required flow rates. Are there any disadvantages to a big pipe other than cost?

2) Do the current pipe sizes look ok?

I assume the pipes which feed the surge tank from the pool via gravity can never be too big.

3) In the Hydraulics 101 thread ( http://www.troublefreepool.com/threads/830-Hydraulics-101-Have-you-lost-your-head ) it says:

"On the return side of the pump, multiple lines can help reduce head loss as well but the number of return lines should never exceed the number of suction or pump cavitation could become an issue."

I don't understand why. Please can someone explain.

4) Also in the Hydraulics 101 thread there is an "Equivalent Pipe/Fitting Size" table. I can't get my head round why where N=1 the equivalent pipe size isn't equal to the actual pipe size. I must be making a fundamental misunderstanding here but don't know what it is.

Thanks

Nick