- Oct 27, 2013

- 207

This side conversation was split from HERE. jblizzle

Not even if the motor were turning backwards?

Mitch, have you checked the rotation of the failed replacement motor with the impeller on?

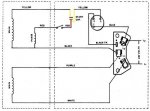

Can you highlight an arrow in its direction?

Something as simple as a miswired run cap can cause reverse rotation.

Both the impeller outlet and volute are at high pressure so cavitation would never occur there.

Not even if the motor were turning backwards?

Mitch, have you checked the rotation of the failed replacement motor with the impeller on?

Can you highlight an arrow in its direction?

Something as simple as a miswired run cap can cause reverse rotation.