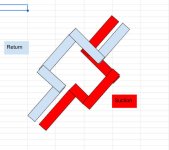

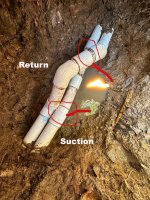

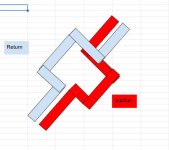

I have a leak in both the return and suction side.

I bought the house with the pool so I have no idea what happened here to necessitate this repair and they the lines are crossed like this. However, as you can see their repair has failed on both the suction AND the return side.

My plan is to cut at the junctions for both pipes and redo it all but I have a couple of questions.

1. Should I use 90deree or 45 degree corners?

2. Should I uset this flex type of pipe again or regular pipe?

Thanks for any help, I need to get his fixed before it gets hot.

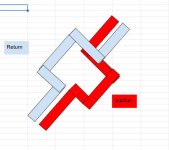

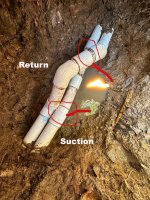

I bought the house with the pool so I have no idea what happened here to necessitate this repair and they the lines are crossed like this. However, as you can see their repair has failed on both the suction AND the return side.

My plan is to cut at the junctions for both pipes and redo it all but I have a couple of questions.

1. Should I use 90deree or 45 degree corners?

2. Should I uset this flex type of pipe again or regular pipe?

Thanks for any help, I need to get his fixed before it gets hot.