There are different bodies that write codes and local authorities vote on which codes to adopt.

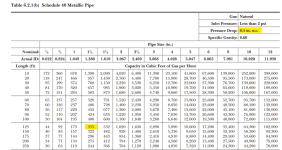

So, your local code dictates things like lines sizing and pressures etc.

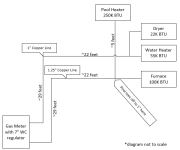

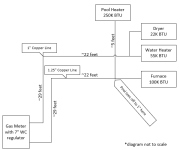

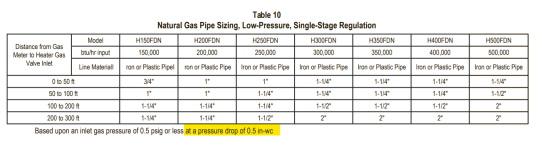

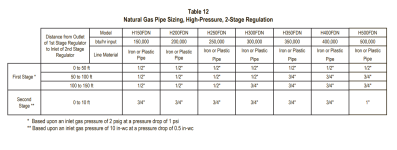

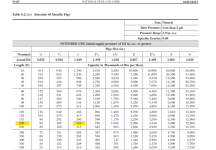

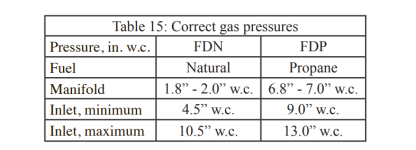

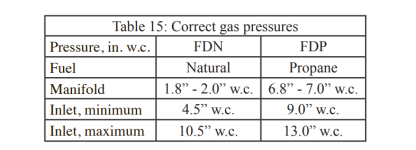

Most manufacturers specify a conservative pressure drop for design of 0.5" w.c for a 7" w.c low pressure delivery installation.

If you follow their guidelines, they are much less likely to deny a warranty claim due to low gas pressure unless it is obvious that the gas pressure was too low.

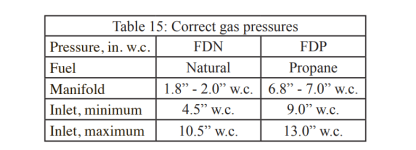

The primary goal is to make sure that the inlet gas pressure never falls below the minimum as specified by the manufacturer.

Any good engineer always adds in margin to any design for safety and I would allow at least 1" of margin for design.

For example, the Hayward Manual specifies a minimum of 4.5", so the minimum design would be to provide at least 5.5" w.c at the inlet.

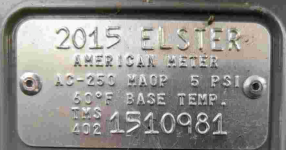

For example, if you had 8" before the meter and a 1" drop across the meter and a 1" drop through the plumbing, then the pressure at the inlet would be 6", which gives a 1.5" w.c margin.

It is always best and highly recommended to follow all of the manufacturer's installations and by law, you have to follow all local code.

Most service people will automatically flag any undersized plumbing on a heater and either refuse to work on the heater or deny any warranty claims, so it is never a good idea to install a heater with plumbing that is smaller than the installation manual specifies.

_____________________________________________________________________________________________

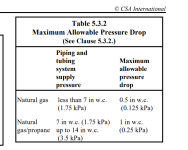

CSA B149.1:20

Natural gas and propane installation code.

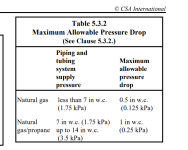

The Natural Gas and Propane Installation Code book specifies the maximum allowable pressure drop in a system, based on the system supply pressure.

Gas piping systems with supply pressures:

less than 7″ w.c. (1.75 kPa) must be designed so the pressure drop does not exceed 0.5″ w.c. (125 Pa).

7″ w.c. to 14″ w.c. (1.75 kPa to 3.5 kPa) must be designed so that the pressure drop does not exceed 1″ w.c. (250 Pa).

_____________________________________________________________________________________________

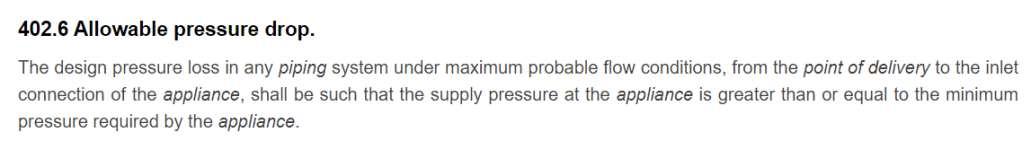

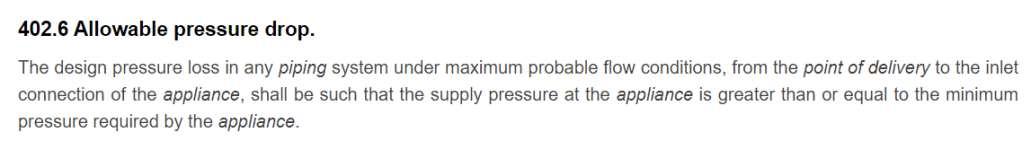

2018 INTERNATIONAL FUEL GAS CODE (IFGC) | ICC DIGITAL CODES

402.5 Allowable Pressure Drop

The design pressure loss in any piping system under maximum probable flow conditions, from the point of delivery to the inlet connection of the appliance, shall be such that the supply pressure at the appliance is greater than or equal to the minimum pressure required by the appliance.

_____________________________________________________________________________________________

54-18 NATIONAL FUEL GAS CODE ANSI Z223.1

5.4.4 Allowable Pressure Drop. The design pressure loss in any piping system under maximum probable flow conditions, from the point of delivery to the inlet connection of the appliance, shall be such that the supply pressure at the appliance is greater than or equal to the minimum pressure required by the appliance.

_____________________________________________________________________________________________

CSA Group was established in 1919 as the Canadian Engineering Standards Association (CESA). It was the first organization in Canada formed exclusively to develop industrial and commercial standards. To better reflect the breadth of CESA's activity, it officially became the Canadian Standards Association (CSA) in 1944 and CSA Group in 2012.