It's standardly 120/240v.

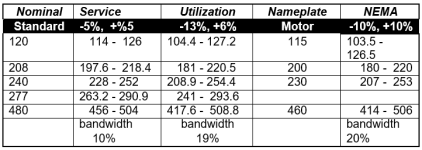

240 volts (Service) - 4.1667% = 230 volts (Utilization) at the appliance due to the voltage drop from the service entrance to the appliance.

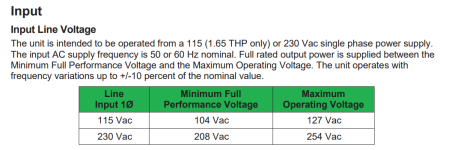

The specifications are +/- 10% of Nameplate voltage.

230 volts + 10% = 253 volts.

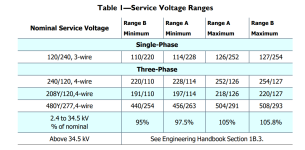

4. Voltage Ranges.

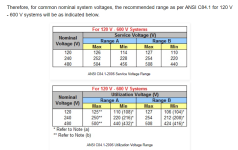

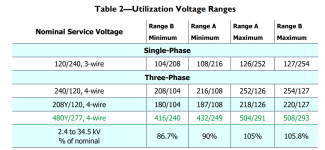

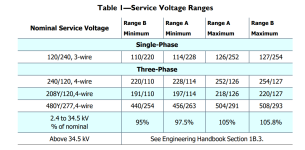

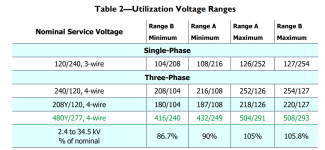

Voltage is divided into two ranges, A and B, and is listed for two locations: service and utilization.

Service voltage is measured at the point of delivery.

Utilization voltage is measured at the terminals of the utilizing equipment.

The difference between minimum service and minimum utilization voltage is intended to allow for voltage drop in the customer's wiring system.

The difference between service and utilization voltage allows for voltage drop in facility wiring between the point of utility delivery and the utilization equipment.

National Electrical Code (NEC) Article 215.2(A)(2) Information Note No. 2 recommends less than three percent (< 3%) of feeder

voltage drop (between the main panel and subpanel) and 210.19 Informational Note No. 1 recommends less than three percent (< 3%) of voltage drop in branch circuits (from the sub-panel to utilization equipment).

An overall combined voltage drop (of branch and feeder) being less than five percent (< 5%) is recommended.

4.1. Range A (Favorable Zone).

Voltage range A is the “favorable” zone, in which the voltage level is near optimal.

4.1.1. Service Voltage.

PacifiCorp’s supply systems shall be designed and operated so that most service voltage levels are within the limits specified for range A.

The occurrence of steady-state service voltages outside these limits should be infrequent.

4.1.2. Utilization Voltage.

Customer systems shall be designed and operated such that service voltage levels are within range A limits and most utilization voltage levels are within the limits specified for range A.

Utilization equipment shall be designed and rated to give fully satisfactory performance throughout this range.

4.2. Range B (Tolerable Zone).

Voltage range B is the “tolerable” zone, in which the voltage level is acceptable but not optimal.

Range B includes voltage levels above and below range A limits that necessarily result from operating conditions.

Although such conditions result in a practical system, they should be limited in extent, frequency, and duration.

Within reasonable time frames, corrective measures should be taken to upgrade voltage levels in range B to those in range A.

In some cases, sustained voltage levels will fall outside range B.

In these instances, utilization equipment may not operate satisfactorily, and protective devices may need to operate.

Such cases should be considered temporary and subject to immediate improvement.