- Mar 22, 2020

- 54

- Pool Size

- 25000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Turbo Cell (T-CELL-5)

I haven't updated my new pool in my bio yet, but will soon. We moved into new house yesterday so we are ready to finish the pool. This gunite was shot in this pool December 15th. We are looking to plaster likely later this week and then fill up. I am on a well, so I conducted water test with my TF 100 and got results below:

PH: 6.8

TA: 40

CH: 50

FC: 0

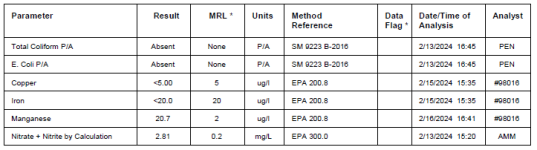

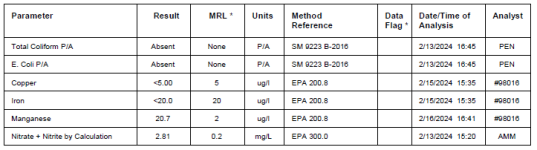

I also sent the water off for testing and got these results:

Overall pretty pleased with the results for drinking water. Should I be concerned with the Manganese level for the pool fill?

PH: 6.8

TA: 40

CH: 50

FC: 0

I also sent the water off for testing and got these results:

Overall pretty pleased with the results for drinking water. Should I be concerned with the Manganese level for the pool fill?