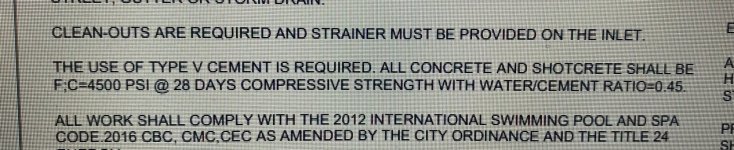

"Though many pool builders feel a 2500 psi (17 MPa) 28-day compressive strength is adequate for pool construction, ASA’s position is that shotcrete must have a minimum 4000 psi (28 MPa) to allow proper encasement of reinforcement, low permeability, and long-term durability.

This is especially important in shotcreted pool shells that are expected to be watertight and provide decades of troublefree service.

This topic is covered in more detail in the “Overview of ASA Position Statements” article on p. 28 of this issue and online in Pool and Recreational Shotcrete Committee Position Statement #1 (

www.shotcrete.org/media/pdf/ASAPositionPaper_PoolRec_1.pdf).

ASA Position Statement #4, “Watertight Shotcrete for Swimming Pools,” explains that ACI 350, “Code Requirements for Environmental Engineering Concrete Structures,” mandates a maximum w/cm of 0.45 with a minimum 4000 psi for concrete intended to have low permeability when exposed to water.

If concrete water-containing structures are exposed to freezing and thawing while saturated (a common occurrence in northern climates), an even lower maximum w/cm of 0.42, with a minimum 4500 psi (31 MPa) is required".

View attachment 539927

The American Shotcrete Association’s (ASA) Pool and Recreational Shotcrete Committee and ASA Board of Direction have reaffirmed a 4000 psi (27.6 MPa) minimum for in-place compressive strength pool concrete